Accelerate production with Heat-free Sealing

Our specialised Baro-seal film layers match the strength of heat-sealing without any heating!

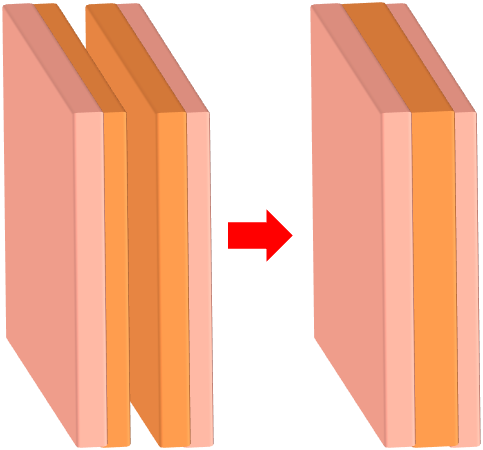

Regular heat-seal

Up to 3x speed!

Baro-seal

50 billion kg

Flexible plastics produced each year.

The fastest-growing packaging category.

~50% of UK rigid plastics are recycled.

Only 5%

for flexibles.

>40% of flexible plastic is un-recyclable multi-material plastic films

50% of plastics

are single-use.

2.5 billion

sachets used every day.

What solutions are there?

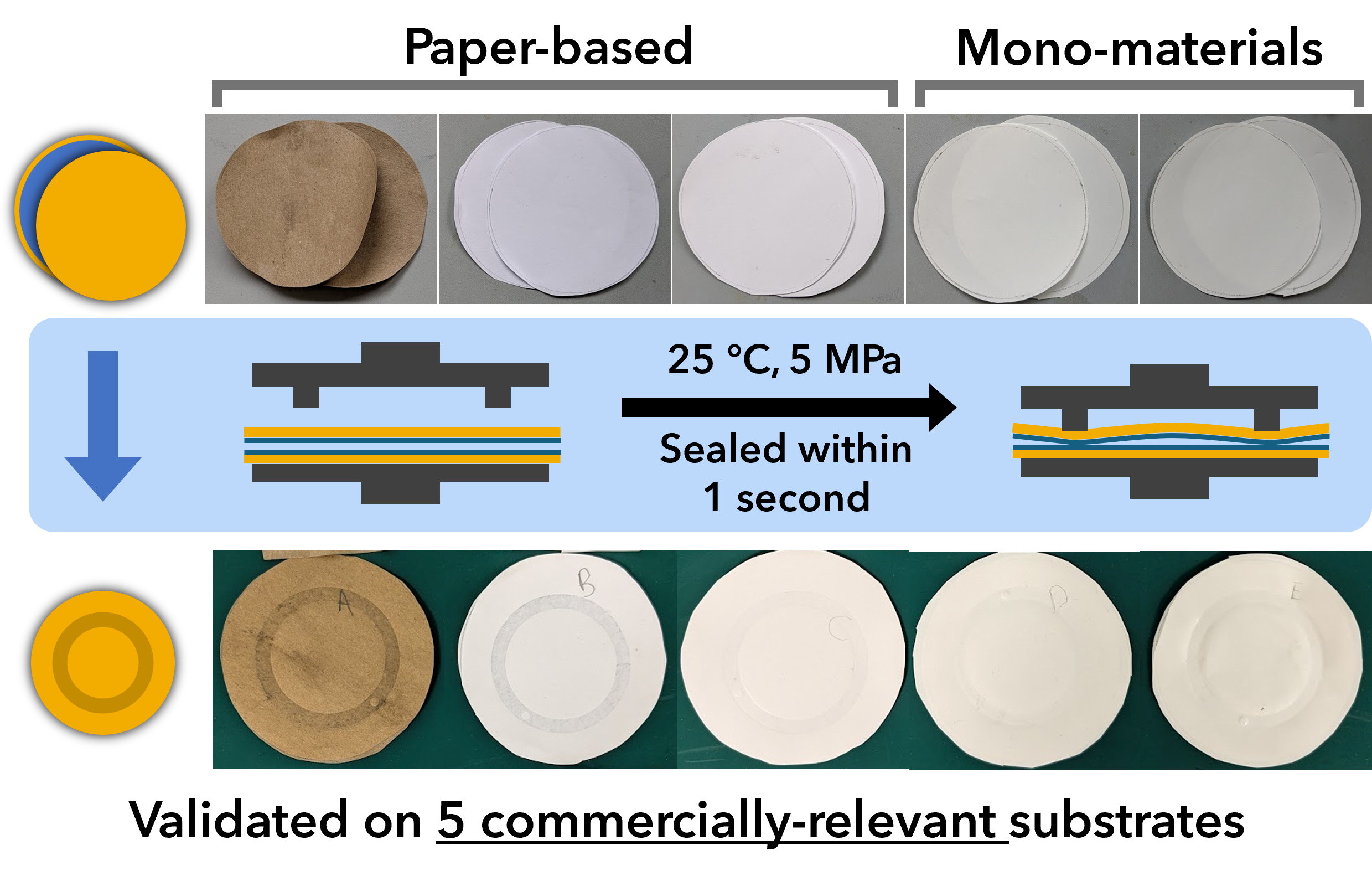

Paper-based

60% global recycling rate

Can currently displace 15% of flexibles

Plastic coatings for sealing and barrier

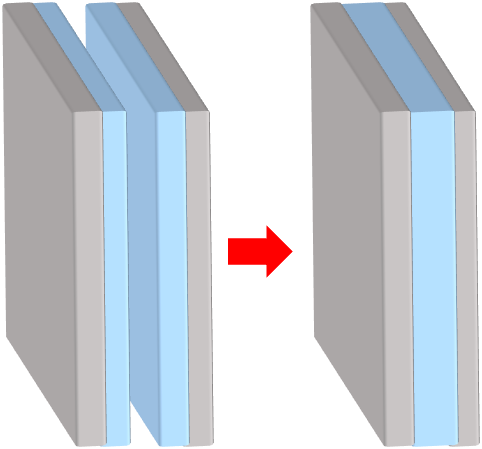

Mono-material plastics

One polymer type (e.g. LDPE, PP)

Can be effectively separated and recycled

Avoids PPWR and EPR taxes

One unavoidable issue. Heat-sealing.

“It is hard to melt the sealant through insulating paper”

“Mono-material films have a narrow heating window”

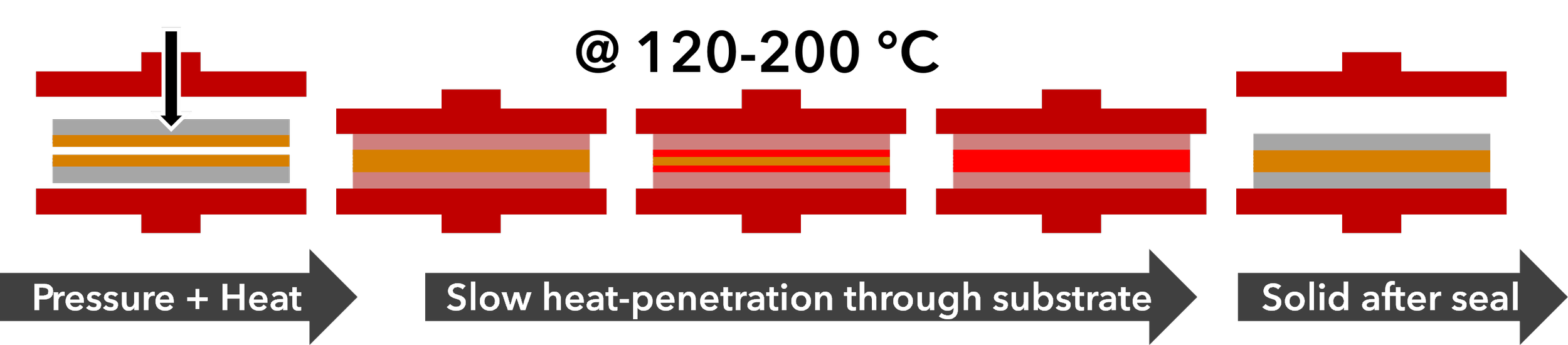

Regular heat-seal

Melts at ~120 °C, but heat must penetrate THROUGH the substrate, which can take several seconds.

Multi-materials: delay can be reduced by increasing the pressing temperature to ~200 °C.

HOWEVER:

Paper-based: thick, thermally insulating, and damaged by high temperatures.

Mono-materials: temperature limited to slightly above the heat-seal temperature.

AS A RESULT, heat-sealing of paper-based and mono-material flexibles is CHALLENGING and SLOW.

~1.5 s per seal

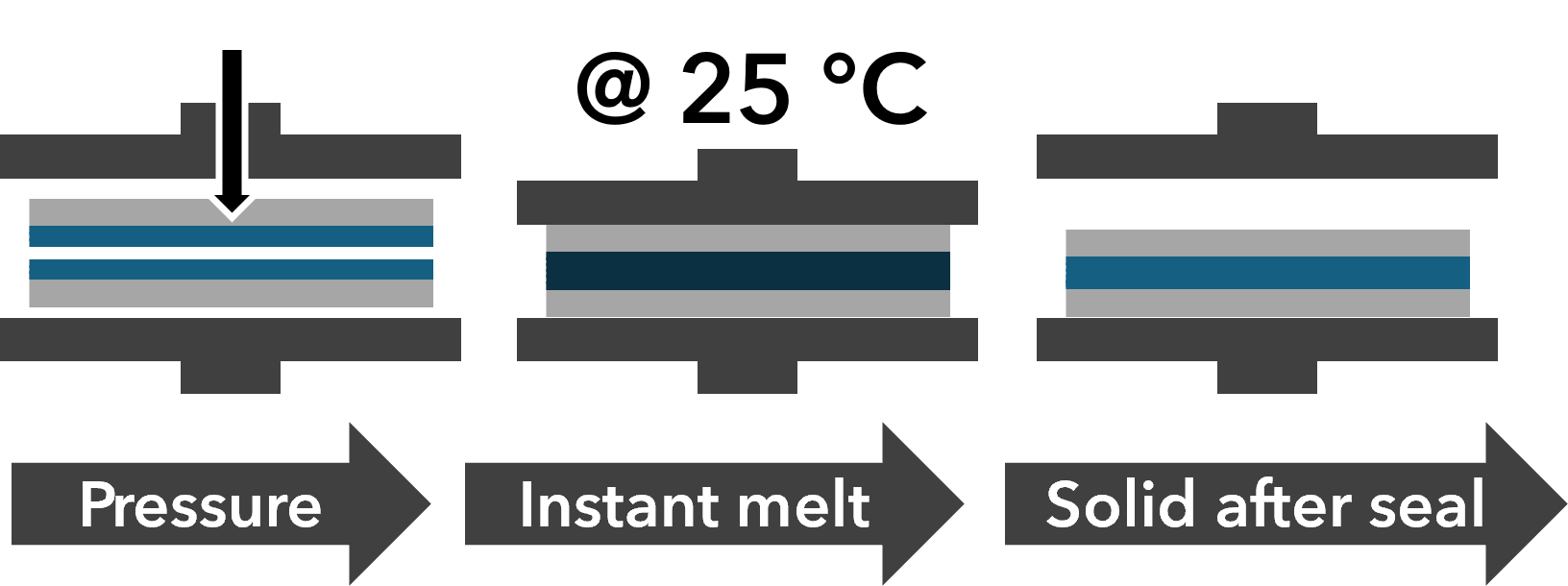

Baro-seal

Baro-seal layer melts at room temperature, with only pressure

Compatible with existing sealing equipment

Matches heat-seal strength: Suitable for solid, gel, and liquid products

Up to 3x the sealing-speed of heat-seal!

Tuneable biodegradation for compostable paper-based applications

~0.5 s per seal

Our Team

Dan MacKinnon

CEO & Co-founder

Dr Dan MacKinnon is an inventor and polymer chemist specialising in the design and commercialisation of innovative advanced materials. He pioneered the development of this technology from fundamental in-lab chemistry and led the ICURe market validation for a high-strength, high-speed, heat-free alternative to heat-sealing. His experience with developing thermo-reversible apparel adhesives, resulting in inventorship on 19 patents, demonstrates his ability to translate innovative chemistry into real-world commercial impact.

Remzi Becer

CSO & Co-founder

Professor Remzi Becer is a renowned expert in sustainable polymer Chemistry, with over 160 peer-reviewed articles published in leading journals and named inventorship on 29 patents. His speciality is in developing polymers to meet specific industrial problems, with experience working on fuel additives, lubricants, reversible adhesives, battery binders, and antibacterial coatings. He heads a research group at the University of Warwick who are world-leading experts on the fundamental chemistry behind our Baro-seal innovation.